You’re staring at your CPAP machine’s warning light because you’ve run out of distilled water. Your steam iron is coughing out white mineral deposits on your best dress shirt. Or maybe you’re simply tired of hauling heavy plastic jugs from the store every week. Making distilled water at home solves all these problems—and you likely already own everything needed to start. This guide reveals three practical methods to produce pure distilled water for medical devices, household appliances, and emergency preparedness—all for pennies per gallon.

Unlike filtered water that merely removes some impurities, distilled water undergoes a complete purification process that eliminates minerals, chemicals, bacteria, and other contaminants. When you learn how to prepare distilled water at home, you gain control over water purity while reducing plastic waste and saving money. Whether you need it for your CPAP machine tonight or want to build an emergency supply, these proven techniques deliver professional results without expensive equipment.

Essential Equipment for Home Distillation

Basic Stovetop Setup

You’ll need just five simple items for effective home distillation: a large stainless steel stockpot (3-5 quart capacity), a heat-resistant glass bowl that fits inside without touching the pot’s bottom, a domed pot lid (glass or stainless steel), ice cubes for condensation, and oven mitts for safe handling. The glass bowl must be smaller than your pot’s diameter to create space for steam circulation. Critical tip: If your lid isn’t domed, invert a regular lid and place ice directly on top—the curved surface creates optimal condensation points.

Optional Upgrades

Enhance your setup with a digital thermometer (0-110°C range) to monitor temperature precisely, activated carbon filters for post-distillation polishing, pH test strips to verify purity, or a countertop electric distiller if you’ll produce water regularly. These additions improve efficiency but aren’t essential for basic operation. Pro tip: Keep a dedicated set of equipment solely for distillation to prevent cross-contamination from cooking residues.

Traditional Stovetop Method

Pre-Distillation Setup

Begin by thoroughly cleaning all equipment with hot, soapy water—any residue contaminates your final product. Position the glass bowl in your pot’s center, ensuring it sits above the water line and won’t float. Fill the pot with source water to one-third capacity; too much water risks splashing into your collection bowl. Verify stability by gently swirling the pot—your collection bowl shouldn’t wobble or tip during operation.

Active Distillation Process

Place the lid upside-down on the pot (handle facing downward toward the bowl), then bring water to a rolling boil. Immediately reduce heat to medium-low for a steady, gentle boil—not violent bubbling that carries impurities into your distilled water. Add fresh ice to the lid every 15 minutes to maintain maximum condensation. Monitor your drip rate: 1-2 drops per second is ideal; faster indicates incomplete purification. Most setups yield 1-2 cups of distilled water per hour of operation.

Post-Distillation Handling

Never rush this step—allow complete cooling (minimum 30 minutes) before handling to prevent burns. Carefully transfer the distilled water using oven mitts to sterilized glass storage containers; plastic can leach chemicals over time. Critical warning: Always label containers with production date—distilled water stored at room temperature lasts only 3-4 days, while refrigerated water remains pure for up to one week.

Solar Still Method (No Electricity)

Emergency Solar Setup

When power is unavailable, this passive method harnesses solar energy to produce clean water. Dig a hole 2 feet wide and 18 inches deep, placing your collection cup in the center. Add vegetation or contaminated water around the cup, then cover the hole tightly with clear plastic sealed at edges using rocks. Create a condensation point by placing a small stone in the plastic’s center. Temperature tip: This method works best when outdoor temperatures exceed 70°F (21°C), yielding 1-2 cups daily in full sun.

Pressure Cooker Method

Enhanced Speed Setup

Transform your pressure cooker into a high-efficiency distiller by removing the pressure weight from the steam vent and attaching copper tubing (3-4 feet long). Coil the tubing through an ice bath for maximum condensation, positioning your collection container below the tubing outlet. Safety note: Never seal the pressure cooker—steam must escape freely through the tubing. This method produces water twice as fast as traditional stovetop distillation, yielding approximately 1 quart per hour.

Quality Control Testing

Simple Purity Checks

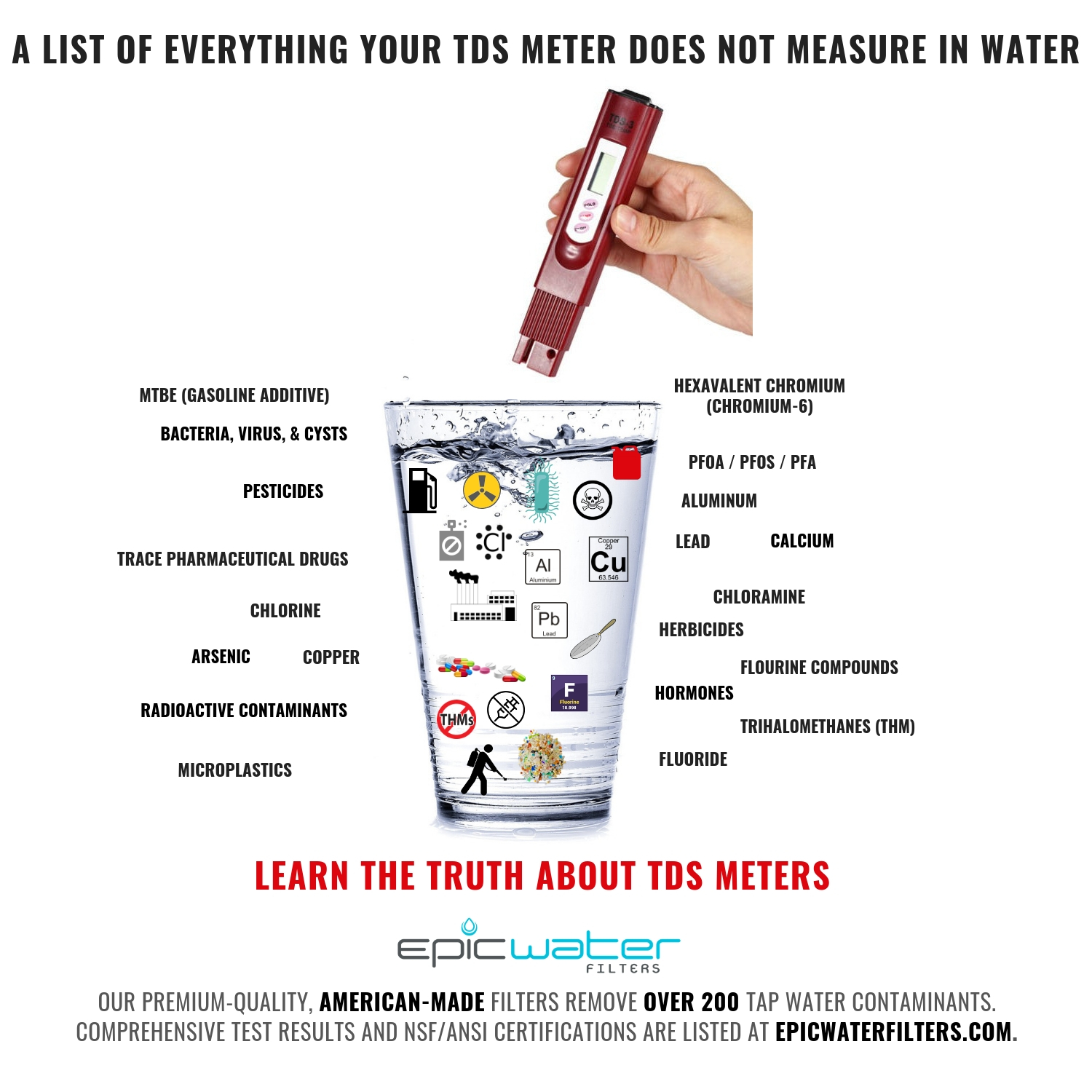

Verify your distilled water’s purity with these quick tests: Hold it against light—it should be crystal clear with zero particles. Evaporate one teaspoon on clean glass; no residue indicates proper distillation. Taste it—it must have a completely flat, neutral flavor without mineral aftertaste. Critical test: Use a TDS meter; genuine distilled water shows 0-3 ppm (parts per million) of dissolved solids.

Common Issues and Solutions

Low Production Problems

If your yield is disappointing, check for steam escaping around the lid—reposition for a tighter seal. Slow condensation means you need more frequent ice replacement or increased surface area. A wobbling collection bowl reduces efficiency; stabilize it with less source water. Pro tip: If boil-over occurs, immediately lower heat and maintain a gentle simmer—violent boiling creates water droplet carryover that contaminates your distilled product.

Contamination Concerns

Residue in your final product means equipment needs deep cleaning with a vinegar solution. Off-flavors often come from plastic storage containers—switch to glass immediately. Cloudy appearance suggests your source water needs pre-filtering through a coffee filter before distillation. Critical warning: Never use distilled water from a setup showing cracks or damage—impurities can leach into your product.

Storage and Shelf Life

Optimal Storage Conditions

Store only in glass containers like Mason jars with tight-fitting lids to prevent airborne contaminants. Keep in a cool, dark location—refrigeration extends shelf life to one week. Labeling system: Write both production date and source water type on each container. Pro tip: For steam irons, add one teaspoon of distilled water to test—if it sputters, your tap water needs distillation before use.

Cost Analysis and Efficiency

DIY vs. Store-Bought

Home production costs just $0.15-0.50 per gallon versus store-bought prices of $0.89-1.50. For weekly users, basic equipment pays for itself in 6-12 months. Energy optimization: Start with hot tap water to reduce heating time, insulate your pot with kitchen towels, and reuse ice melt as source water for your next batch.

Safety Best Practices

Burn Prevention

Never leave active distillation unattended—set 30-minute timer reminders. Use back burners when possible and turn pot handles inward to prevent accidental tipping. Critical warning: Keep your workspace clear of towels and flammable materials—steam distillation creates significant heat.

Equipment Safety

Verify all glass components are heat-resistant (Pyrex or borosilicate) and check for cracks before each use. Ensure your setup is stable—a wobbling bowl spills boiling water. If using an electric distiller, provide adequate ventilation to prevent moisture buildup.

Applications and Usage Guidelines

Medical and Health Uses

Distilled water prevents mineral buildup in CPAP machine humidifier chambers and ensures safe nasal irrigation with neti pots. It’s essential for infant formula preparation and medical equipment sterilization. Pro tip: For CPAP machines, distilled water extends equipment life by 30-50% compared to filtered water.

Household Applications

Eliminate mineral scaling in steam irons and extend humidifier filter life by using distilled water. It’s crucial for automotive cooling systems mixed with antifreeze and creates streak-free results for window cleaning. Expert note: In aquariums, distilled water benefits sensitive fish species but requires mineral supplementation for long-term health.

Making distilled water at home puts you in control of water purity while saving money and reducing environmental impact. Start with the basic stovetop method—it requires minimal investment and produces excellent results immediately. As you gain confidence, explore solar distillation for emergency preparedness or invest in an electric distiller for regular production needs.

Remember that consistency beats complexity: a simple, repeatable process yields better long-term results than elaborate setups you abandon after one use. Your medical devices, household appliances, and wallet will thank you every time you choose to prepare distilled water at home. With these techniques mastered, you’ll never worry about running out of this essential resource again.