Mounting tires at home saves you $150-$300 per set compared to professional installation while giving you complete control over the process. Whether you’re switching to winter tires or upgrading to performance rubber, mastering this essential automotive skill puts you in charge of your vehicle’s safety and performance. With the right tools, proper safety precautions, and systematic approach, you can successfully mount tires at home—no garage required. This guide reveals the exact process professionals use, adapted for home mechanics with basic equipment.

Essential Safety Gear Setup for Tire Mounting

Tire mounting involves forces exceeding 5,000 pounds and high-pressure air—treat both with respect to avoid serious injury. Protecting yourself isn’t optional; it’s the foundation of any successful home tire mounting project.

Required Personal Protective Equipment

Safety glasses protect against rubber fragments that can fly at high velocity when breaking stubborn tire beads. Heavy-duty gloves prevent hand lacerations from sharp wheel edges and provide critical grip during tire manipulation. Steel-toed boots guard against dropped wheels weighing 20-50 pounds each—trust me, you don’t want to experience that pain. Add ear protection when operating air compressors continuously to prevent hearing damage.

Workspace Requirements

Choose a level concrete surface with 6 feet of clearance around your vehicle—uneven ground causes dangerous instability. Position wheel chocks behind opposite wheels to prevent movement while working. Lay cardboard or rubber mats to protect wheels from scratches and catch lubricant spills. Ensure your workspace has 150+ PSI air compressor capacity with adequate ventilation for exhaust fumes, especially in enclosed garages.

Core Tire Mounting Tools You Actually Need

Primary Equipment List

- Bead breaker: Manual screw-type or hydraulic unit rated for 5,000+ pounds force (don’t attempt without this)

- Tire irons: 2-3 pieces, 24-30 inches with curved ends for proper leverage

- Rim protectors: Plastic guards preventing wheel scratches during prying

- Valve core tool: Essential for complete deflation and inflation control

- Tire lubricant: Specialized mounting paste or 1:10 dish soap dilution

- Air compressor: Minimum 150 PSI with accurate tire gauge

- Bead seating tank: High-volume air blast for stubborn tire beads

Supporting Equipment You’ll Thank Yourself For

Add a quality torque wrench for proper lug nut installation (80-100 ft-lbs typical for passenger vehicles). Jack stands rated for your vehicle weight (minimum 2-ton capacity) provide critical safety support—never work under a vehicle supported only by a jack. A static wheel balancer ensures smooth operation post-installation, while chalk marks help track tire/wheel orientation during the mounting process.

Pre-Mounting Inspection That Prevents Costly Mistakes

Tire and Wheel Assessment Checklist

Examine new tires for manufacturing defects before mounting—check sidewalls for bulges, cuts, or embedded debris that could cause failure. Verify size compatibility using format like P215/65R15, ensuring it matches your vehicle specifications exactly. Inspect wheels thoroughly for cracks, bends, or corrosion that could compromise the tire seal. Clean wheel mating surfaces with a wire brush to remove corrosion and old adhesive residue—this step prevents air leaks later.

Compatibility Verification Before You Start

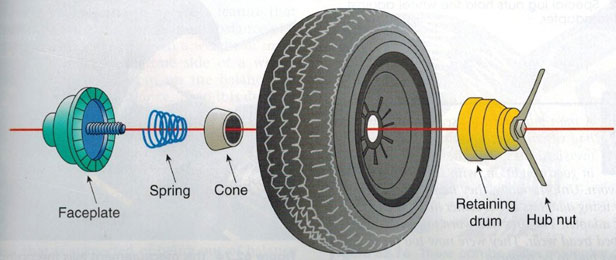

Confirm wheel bolt pattern matches your vehicle hubs (common: 5×114.3mm or 5x120mm) using a simple bolt pattern gauge. Check wheel offset and backspacing for proper fitment without brake or suspension interference—measure clearance with a tape measure. Ensure center bore diameter matches or exceeds your vehicle’s hub size for hub-centric mounting stability. Verify load rating exceeds your vehicle’s requirements—typically 1,500+ pounds per tire for passenger vehicles.

Tire Removal Process Without Damaging Components

Wheel Removal and Safe Deflation

Safely lift your vehicle using proper jack points specified in your owner’s manual, supporting with jack stands before removing wheels. Break lug nuts loose while vehicle is on ground, then remove completely once elevated. Critical step: Deflate the tire completely by removing the valve core—this prevents explosive decompression during bead breaking. Mark the tire’s position relative to the wheel using chalk for potential reuse balancing.

Breaking Stubborn Tire Beads Safely

Position your bead breaker perpendicular to the tire sidewall, 180 degrees from the valve stem. Apply gradual pressure until you hear the distinctive “pop” indicating bead release—rushing this causes wheel damage. Rotate the wheel 180 degrees and repeat for the opposite bead. For stubborn beads, apply penetrating oil and wait 10-15 minutes before retrying. Exercise extreme caution to avoid wheel damage during this high-force process.

Complete Tire Removal Technique

Insert tire iron between tire bead and wheel rim, using rim protectors to prevent scratching. Pry upward progressively while maintaining consistent pressure, using a second tire iron to hold progress. Work around the circumference systematically, ensuring complete bead removal from the wheel’s drop center before attempting full tire removal. Apply lubricant to stubborn areas to reduce resistance—never force it.

New Tire Installation Without Pinching the Bead

Tire Preparation and Strategic Positioning

Inspect your new tire for directional arrows or rotation indicators molded into the sidewall—mounting backwards reduces performance. Liberally apply tire lubricant to both tire beads and wheel rim edges—this prevents damage and eases installation. Position the tire at a 45-degree angle to the wheel, starting installation at the valve stem area for easier access. Pro tip: Warm tires to room temperature first—cold rubber is stiff and difficult to mount.

Bead Installation Method That Works Every Time

Use tire irons to work the first bead over the rim edge, maintaining even pressure distribution to prevent pinching. Install the second bead using the drop center technique—ensure the bead sits in the wheel’s deepest section to reduce resistance. Work methodically around the circumference, using lubricant liberally on resistant sections. For difficult installations, apply body weight strategically while maintaining control.

Bead Seating and Inflation Without Blowouts

Initial Seating Process Done Right

Reinstall the valve core before inflation—attempting without it causes dangerous air loss. Connect your air compressor and inflate rapidly to 40-45 PSI to seat both beads—you’ll hear two distinct “popping” sounds as each bead seats against the rim. Check the bead seating indicators (small raised dots on tire sidewalls) for even spacing around the entire circumference. Reduce pressure to your vehicle’s specifications after successful seating.

Troubleshooting Stubborn Beads Safely

If beads refuse to seat, increase inflation pressure to 50-55 PSI maximum—never exceed the tire’s maximum pressure rating. Apply additional lubricant around the entire bead circumference. Use a ratchet strap around the tire center to compress and force beads outward during inflation. Remove the valve core for maximum air flow during the seating process, but immediately reinstall it once seated.

Balancing and Final Installation for Smooth Operation

Wheel Balancing Procedure for Home Mechanics

Mount the wheel/tire assembly on your balancer, selecting proper centering cones for accurate results. Spin the assembly to identify heavy spots, marking them with chalk. Add wheel weights opposite heavy areas, starting with small 0.25-ounce increments. Recheck balance after each adjustment, achieving within 0.25-ounce tolerance for smooth operation. Warning: Skipping balancing causes premature tire wear and vibration.

Final Wheel Installation Done Properly

Clean the wheel hub surface thoroughly and apply a thin layer of anti-seize compound to prevent future corrosion. Install wheels using hand-threading initially to avoid cross-threading. Lower the vehicle until the tire makes contact but full weight isn’t on the ground. Torque lug nuts in a star pattern to manufacturer specifications—typically 80-100 ft-lbs for passenger vehicles. Recheck torque after 50-100 miles of driving.

Common Problems and Quick Solutions

Bead Seating Failures Fixed in Minutes

Persistent bead seating issues often stem from insufficient lubrication or debris on wheel surfaces. Clean both tire beads and wheel thoroughly with brake cleaner. Apply mounting paste liberally and use a bead seating tank for high-volume air delivery. In extreme cases, position the tire in direct sunlight for 30 minutes to soften rubber before retrying—heat makes rubber more pliable.

Vibration After Installation: Immediate Fixes

Post-installation vibration typically indicates balance issues or wheel damage. Recheck wheel balance, ensuring weights haven’t fallen off during handling. Inspect wheels for bends using a straight edge—runout should remain under 0.030 inches. Consider road force balancing if standard methods don’t resolve vibration, particularly with low-profile tires that magnify imperfections.

When to Call Professionals for Help

Seek professional assistance for run-flat tire installations—these require specialized equipment and techniques. Low-profile tires (aspect ratio under 45) present significant challenges due to reduced sidewall flexibility. Professional mounting becomes essential for tires exceeding 35 inches in diameter or when working with expensive aftermarket wheels you can’t afford to damage. Remember: some projects are better left to experts with commercial-grade equipment.

Mastering how to mount tires at home delivers immediate cost savings and deeper automotive understanding. Start with easier tire sizes and gradually tackle more challenging installations as your confidence grows. Always prioritize safety over speed—properly mounted tires mean the difference between safe driving and dangerous blowouts. When in doubt, consult a professional; there’s no shame in knowing your limits when it comes to critical vehicle components.