When the power goes out, the last thing you want is a generator that’s too small to keep your essentials running—or one that’s oversized and wastes fuel. Whether you’re preparing for hurricane season or just want backup power security, getting the sizing right makes the difference between comfort and frustration during outages. This guide walks you through the exact steps to calculate your home’s generator requirements, from basic wattage calculations to advanced load management strategies. You’ll learn how to avoid common sizing mistakes that leave homeowners in the dark, plus discover professional techniques for precise load assessment.

Why Starting Watts Determine Your Generator Size

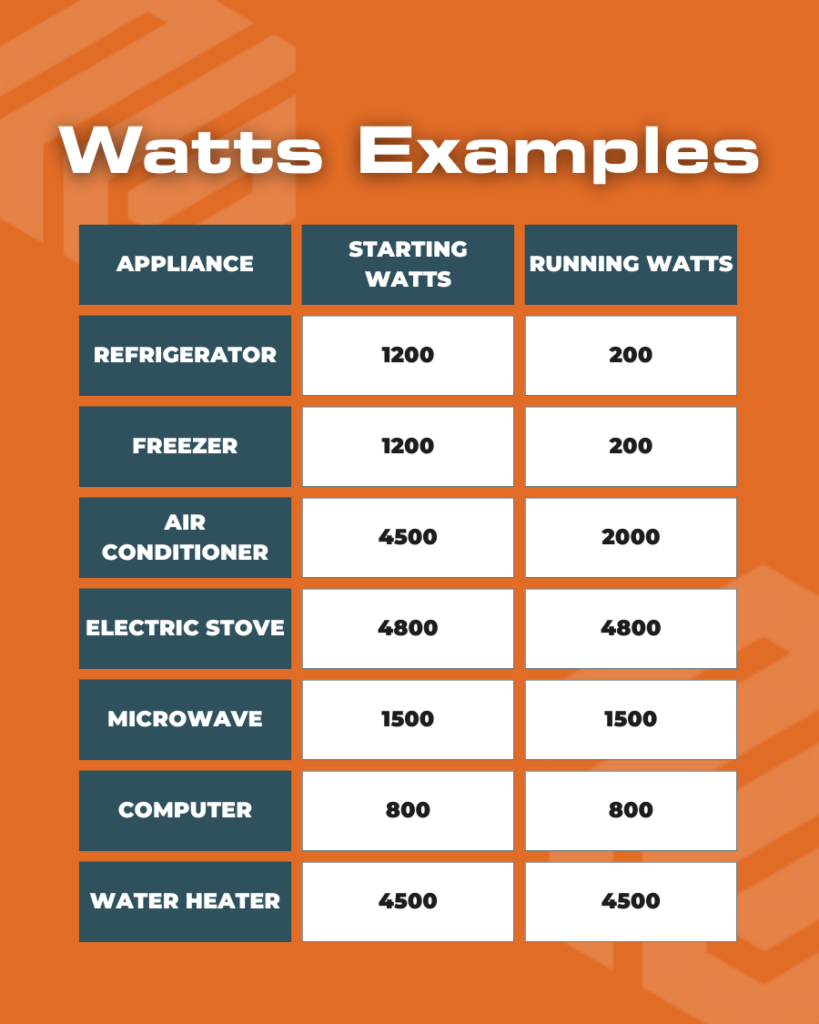

Most homeowners make the critical error of calculating generator size based solely on appliance running watts, ignoring the crucial starting surge requirements that actually determine your minimum generator capacity. Motor-driven appliances like refrigerators, air conditioners, and well pumps need significantly more power to start than to run continuously—typically 2-3 times their running wattage. Your 1,000W well pump label hides the reality that it actually demands 3,000W for those critical first seconds when the motor engages. This distinction between running watts (continuous operation) and starting watts (initial surge) is why so many undersized generators fail when you need them most.

Generators operate at approximately 0.8 power factor, meaning a 5,000W unit delivers only 4,000W of usable power. This built-in derating protects against power quality issues but requires you to factor this buffer into your calculations from the very beginning. Ignoring this technical reality leads to generators that can’t handle the actual electrical demands of your home during critical startup moments.

How to Find Accurate Wattage Specifications

Locate the nameplate on each appliance or consult the owner’s manual for precise power requirements—never rely on guesswork. For devices without wattage labels, calculate starting watts using this formula: Starting Watts = Locked Rotor Amperage (LRA) × Voltage. Motor-driven appliances will clearly indicate LRA values, while resistive loads like incandescent bulbs or electric heaters have identical running and starting wattage since they lack motors.

Essential Load Inventory Checklist for Homeowners

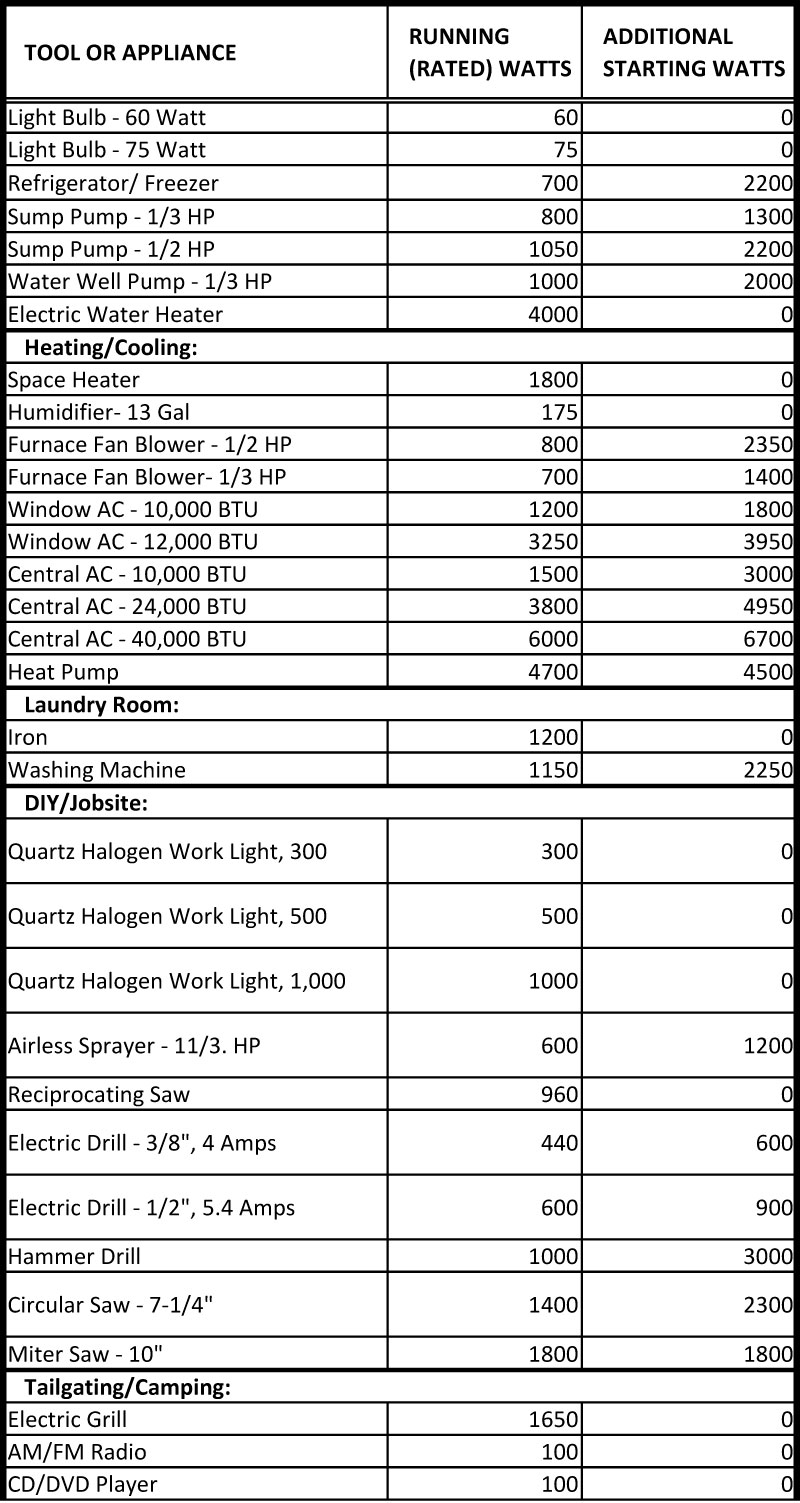

Grab your smartphone or notepad and conduct a room-by-room assessment of what you truly need during an outage—not everything you own, but the essentials for safety, health, and basic comfort. Your load inventory must include both voltage requirements (120V or 240V) and both running and starting wattage for each item. Focus on these priority categories to avoid overwhelming yourself with unnecessary calculations.

Critical safety systems: Refrigerator/freezer, well pump or sump pump, medical equipment, and security systems should top your list. These aren’t conveniences—they’re essential for health and property protection during extended outages.

Basic comfort essentials: Select lighting circuits, internet equipment, and limited HVAC operation (like running just one zone) maintain sanity during power disruptions. Don’t forget your phone chargers and a single entertainment device—these small loads add up quickly.

Avoid these common inventory mistakes: Including everything in your home, ignoring motor starting surges, and forgetting that some appliances cycle on and off. Be realistic about what you’ll actually need during an outage rather than creating an unmanageable load list.

Calculate Your Home’s Actual Running Load Requirements

Add up the running watts only for appliances that will operate simultaneously during normal conditions—not the theoretical maximum of everything running at once. Your refrigerator compressor cycles on and off, while your well pump runs intermittently based on water usage. Use realistic patterns rather than worst-case scenarios to avoid massive over-sizing.

Real-world running loads for common essentials:

– Modern refrigerator: 700-800W

– Whole-house LED lighting: 150-250W

– Internet equipment: 80-120W

– 1/2 HP well pump: 900-1,100W

– Security system: 40-60W

– Entertainment center: 200-400W

Sample calculation: Refrigerator (800W) + Lighting (200W) + Internet (100W) + Well pump (1,000W) + Security (50W) + Electronics (300W) = 2,450W total running load. This represents a realistic simultaneous load rather than an improbable maximum.

Identify the Critical Starting Load That Determines Your Minimum Size

This single step prevents the most common generator sizing failure. Scan your inventory list and find the appliance with the largest starting wattage—this value determines your minimum generator capacity. Even if you plan to run multiple motor-driven appliances, you only add the largest single starting load to your calculations because motors don’t all start simultaneously under normal conditions.

Starting load comparisons:

– Central air conditioner (3-ton): 10,500W starting

– Well pump (1/2 HP): 3,000W starting

– Refrigerator: 2,400W starting

– Freezer: 2,100W starting

– Electric range: 4,500W starting

In most homes without central AC, the well pump creates the biggest starting surge challenge. For homes with central air, this becomes the dominant factor that drives generator sizing requirements significantly higher than expected.

Final Calculation Formula for Reliable Generator Sizing

Use this precise formula to determine your minimum generator size: Total Generator Size = Total Running Load + Highest Starting Load. Using our earlier example: 2,450W running load + 3,000W well pump starting load = 5,450W minimum capacity. Always round up to the next standard generator size (in this case, 6,000W).

Don’t skip this critical step: Add a 20-25% safety margin for calculation errors, future electrical additions, and generator aging. Our example becomes 5,450W × 1.25 = 6,812W, meaning you should purchase a 7,500W generator for reliable performance. This buffer prevents your generator from running at maximum capacity, which reduces its lifespan and creates power quality issues.

Smart Load Management Strategies to Reduce Generator Size

Want to use a smaller, more affordable generator? Implement these load management techniques to significantly reduce your required capacity without sacrificing essential functions. Priority load systems automatically shed non-essential circuits when demand exceeds capacity, ensuring critical loads stay powered during motor startups.

Manual load control offers a budget-friendly alternative through inexpensive switches that let you control which circuits receive power. During outages, you might temporarily turn off the electric water heater while running the well pump, then reverse the process when needed. This simple strategy can reduce your generator requirements by 30-40%.

Soft start devices installed on air conditioners or well pumps reduce motor starting loads by 50-70%. A 4-ton air conditioner that normally needs 15,000W to start might only require 7,500W with soft start technology—potentially allowing you to choose a smaller, less expensive generator.

Generator Type Selection Based on Your Calculated Load

Portable generators (2-12kW) work well for essential loads only but require manual operation and frequent refueling. They’re cost-effective for short outages but become cumbersome during extended power failures. Expect 4-8 hours of runtime per fuel tank depending on load percentage.

Standby generators (7-50kW+) provide automatic whole-house capability with permanent fuel connections. These systems include automatic transfer switches that activate within seconds of an outage. The higher upfront cost delivers unmatched convenience and reliability, especially for homes with critical medical equipment or freeze protection needs.

Your fuel choice impacts sizing calculations—natural gas generators produce 10-15% less power than propane equivalents due to lower energy content. Diesel offers the highest energy density for large loads but requires more complex installation and maintenance.

Quick Sizing Checklist Before You Buy

Verify these essentials before purchasing any generator to avoid costly mistakes:

- List all essential loads with verified running and starting watts (not estimates)

- Calculate total running load based on realistic simultaneous operation

- Identify largest starting load among motor-driven appliances

- Add 20-25% safety margin for future growth and calculation errors

- Consider load management to potentially reduce size requirements

- Factor fuel type derating for natural gas installations

- Plan for professional installation and local code compliance

Annual Maintenance and Load Verification

Your generator sizing isn’t a one-time calculation. Review load requirements annually as your electrical usage evolves. Track actual performance during outages to verify your calculations match real-world conditions. Install a power monitor on your generator output to track voltage stability and actual load percentages during operation.

Critical maintenance includes:

– Annual load testing at 50%, 75%, and 100% capacity

– Monitoring fuel consumption per kilowatt-hour generated

– Checking voltage and frequency stability under various loads

– Verifying load acceptance performance matches specifications

Getting your generator size right prevents expensive mistakes and ensures reliable backup power when you need it most. Start with the basic calculation, then refine based on your specific situation and future plans. Remember that slightly oversizing beats undersizing every time—running a generator at 75% capacity extends its lifespan and provides better power quality than maxing out a smaller unit. When you’ve correctly calculated how to size a generator for home use, you’ll sleep easier knowing your power needs are covered during the next outage.